Universal chamber HYBRID

The universal installation 3 in 1 can run in three modes:

1. smokehouse for heat treatment;

2. smokehouse for fermentation and cold smoking of not heat-treated products;

3. drying chamber for ripening of not heat-treated products.

It uses two alternatives of product drying:

1. heat drying in mode 1;

2. low-temperature drying using the condensation of water steam on the cooler's plate in mode 2 and 3.

Maximal use of the installation with three modes – heat treatment during the day, fermentation and ripening of not heat-treated products in the night and at the weekends.

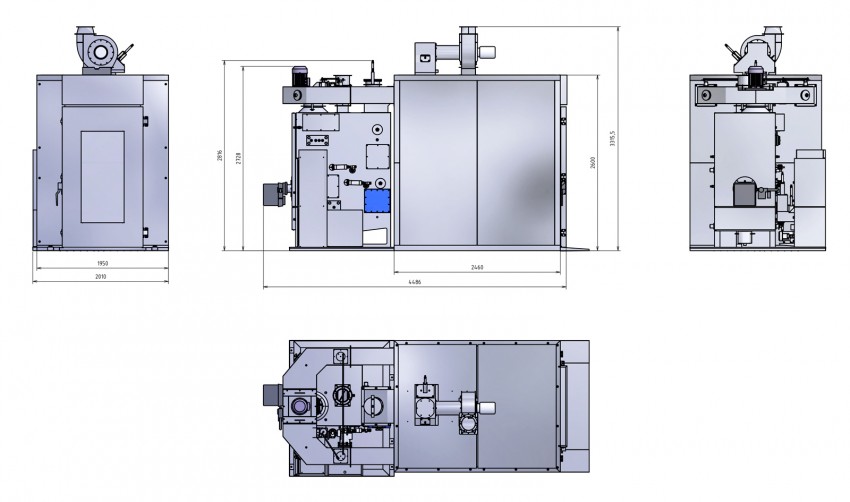

Universal chamber hybrid-two-wheel drive:

Device characteristics:

- It enables a full-value production of all meat products.

The installation has got a fully automatic running and continuous transfer among each of its modes without any modifications. - Great results in the smoking of products with high surface humidity and products with temperature-sensitivity (fish, cheese, tofu).

- It consists of two parts, is portable and can be placed in a room without any construction works.

- The installation includes its own cooler and air compressor; it runs on electricity and water.

- During the whole smoking procedure a controlled Smoke-generator Natural is regulated in the temperature extent of pyrolysis frass that is optimal for the production of smoke with qualities required for product smoking.

- The technological process is controlled by a new generation system iRauch that ensures automatic running of the smokehouse. Its software enables arbitrary phase sequence of the technological process as well as creation of user application programs with different parameters (temperature, humidity, time, air circulation) in each phase of the process. It also ensures the monitoring and recording of smokehouse parameters with reference to HACCP and Food Quality Control Inspection.

- Simple, well-arranged and intuitive control of the installation with a touch screen.

- Its case is made of several parts which are put together at the customers'. No assembling gap is needed as each of its parts can go through ordinary door. The housing of the installation's parts is made of stainless steel and afterwards filled on a special production line with bi-component polyurethane foam which is stabilized by pressure and temperature. Thanks to this, a perfect thermal isolation of chamber walls, or more precisely ecological and economic running of the chamber, is guaranteed.

- The installation includes an automatic wash-system which ensures the wash-up of all inaccessible parts of the smokehouse.